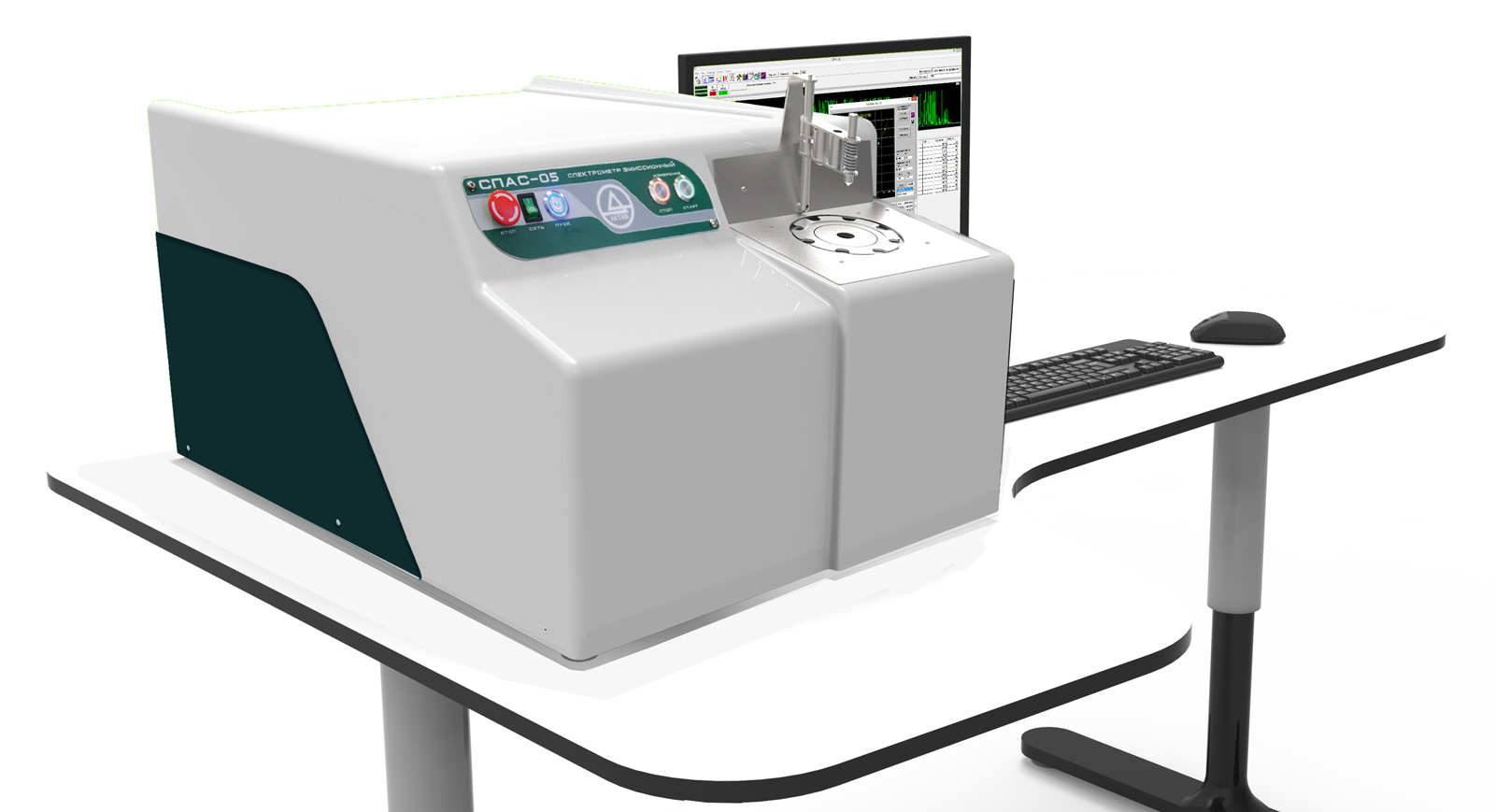

Optical emission spectrometer (OES) SPAS-05 for metal analysis

on request

please, contact the manager

SPAS-05 is an optimal choice for customers, who need rapidity, high technical features, safety and high accuracy of the results of identification of chemical composition of metal production under minimum costs on the purchase, introduction and exploitation of the device.

SPAS-05 is an optimal choice for customers, who need rapidity, high technical features, safety and high accuracy of the results of identification of chemical composition of metal production under minimum costs on the purchase, introduction and exploitation of the device.

The sphere of application:

industrial analytical laboratories of metallurgical and manufacturing enterprises

express-analysis of alloys while melting in the workshop

identification of alloy grade in the storehouse

Scientific Research Institutes and Educational Institutions

Analytical performance

SPAS-05 identifies the composition of as well as ferrous alloys (all types of steel and cast iron) and non-ferrous alloys of any matrices (Al, Cu, Zn, Ni, Ti, Mg, Co, etc.).

The accuracy of measurements is better than the existing requirements of GOSTs (Russian standards of measuring tools).

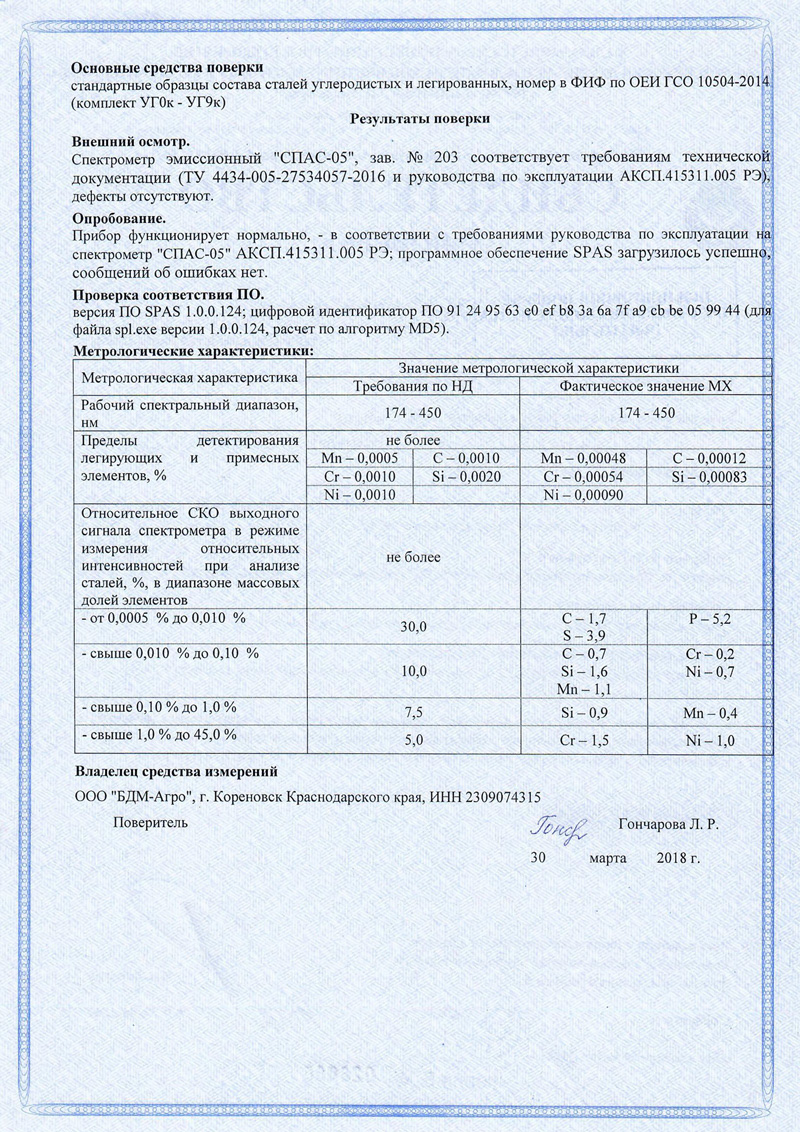

Each instrument passes through the state initial inspection at The D.I.Mendeleev All-Russian Institute For Metrology (VNIIM).

These tests verify the high metrological qualities of SPAS-05 spectrometers and equate them to the world leaders.

Table 1.

The example of analysis accuracy of low alloy steel sample

| Element | Cert. value, % | Cert dev, % | Meas. value, % | Diff, % |

|---|---|---|---|---|

| C | 0.088 | 0.001 | 0.0902 | 0.0022 |

| Si | 0.135 | 0.004 | 0.1344 | 0.0006 |

| Mn | 0.177 | 0.002 | 0.1713 | 0.0057 |

| P | 0.0067 | 0.0004 | 0.0061 | 0.0006 |

| S | 0.0055 | 0.0006 | 0.0049 | 0.0006 |

| Cr | 1.51 | 0.01 | 1.507 | 0.003 |

| Ni | 1.87 | 0.01 | 1.851 | 0.019 |

| Cu | 0.49 | 0.003 | 0.4811 | 0.0089 |

| Mo | 0.049 | 0.001 | 0.0518 | 0.0028 |

| W | 0.43 | 0.01 | 0.4262 | 0.0038 |

| Ti | 0.027 | 0.002 | 0.024 | 0.003 |

| V | 0.121 | 0.002 | 0.123 | 0.002 |

| Al | 0.47 | 0.02 | 0.458 | 0.012 |

Table 2

The example of analysis accuracy of low alloy cast iron sample

| Element | Cert. value, % | Cert dev, % | Meas. value, % | Diff, % |

|---|---|---|---|---|

| C | 2.94 | 0.02 | 2.904 | 0.036 |

| Si | 1.5 | 0.01 | 1.501 | 0.001 |

| Mn | 0.454 | 0.004 | 0.446 | 0.008 |

| P | 0.232 | 0.004 | 0.223 | 0.009 |

| S | 0.036 | 0.01 | 0.04 | 0.004 |

| Cr | 0.476 | 0.004 | 0.4725 | 0.0035 |

| Ni | 0.542 | 0.004 | 0.529 | 0.013 |

| Cu | 0.7 | 0.01 | 0.68 | 0.02 |

| Mo | 0.406 | 0.005 | 0.401 | 0.005 |

| Ti | 0.027 | 0.001 | 0.028 | 0.001 |

| V | 0.086 | 0.001 | 0.0847 | 0.0013 |

Table 3

The example of analysis accuracy of stainless steel sample

| Element | Cert. value, % | Cert dev, % | Meas. value, % | Diff, % |

|---|---|---|---|---|

| C | 0.038 | 0.001 | 0.0367 | 0.0013 |

| Si | 0.65 | 0.01 | 0.638 | 0.012 |

| Mn | 2.05 | 0.02 | 2 | 0.05 |

| P | 0.0132 | 0.0005 | 0.0117 | 0.0015 |

| S | 0.017 | 0.0007 | 0.0186 | 0.0016 |

| Cr | 15.01 | 0.07 | 15.18 | 0.17 |

| Ni | 12.04 | 0.05 | 11.88 | 0.16 |

| Cu | 0.045 | 0.001 | 0.0437 | 0.0013 |

| Mo | 0.141 | 0.004 | 0.137 | 0.004 |

| W | 0.05 | 0.001 | 0.053 | 0.003 |

| Ti | 0.26 | 0.01 | 0.271 | 0.0011 |

| V | 0.128 | 0.006 | 0.132 | 0.004 |

| Al | 0.01 | 0.003 | 0.0118 | 0.0018 |

Specifications

Case

The new design of the case and using of a composite material with low thermal conductivity provides:

- perfect electromagnetic interference immunity;

- sustainability to temperature fluctuations;

- protection from environmental influence;

- easy accessibility to construction with routine maintenance.

Optics

Vacuum option:

- allows to get the best analytical performance among spectrometers based on CCD;

- reduces the dependence on temperature fluctuations.

New polychromator construction:

- more durable and repairable;

- is resistant to vibrations and transportation;

- allows maximum fine-tune the key spectral lines;

- allows for reconfiguration in the event of significant changes in analytical tasks.

Spark stand

New design provides:

- fast putting and easy change of analysing samples;

- easy maintenance of tungsten electrode;

- easy access to protective glass;

- easy access to lense.

Spark source

The new spark generator allows to choose optimal parameters for posed analytical task.

Various modes and their combinations (high-energy sparking, spark modes with various options, including quasi-arc) allow to solve analytical tasks of wide range

Software

Spectrometer SPAS-05 software is adapted for Microsoft Windows and has a following wide range of functions:

- gas and vacuum system control;

- graphic representation of spectrum with opportunity to identify spectral lines;

- export of analysis results into MS Word and OpenOffice;

- calculation of concentrations in % and ppm;

- database of alloys with opportunity to add your own grades;

- one-point and two-point recalibration (standardization);

- analysis process indication;

- qualitative analysis possibility if there is no corresponding analytical methods installed on the spectrometer;

- protection against unauthorized access to factory calibrations (Assistant mode) with the possibility of such work under the control of the representative of the manufacturer (Engineer mode);

- possibility to create your own analytical methods.

Do you have any questions?

Do you have any questions?

Call us: +7 (812) 337-50-49